When it comes to the world of pipe fittings, one of the most reliable and important components is the dresser coupling. Whether you’re in construction, plumbing, or industrial maintenance, understanding the role of dresser couplings in your system is crucial for ensuring longevity and performance. In this post, we’ll dive deep into what dresser couplings are, how they work, and why they’re essential for your pipeline systems.

What is a Dresser Coupling?

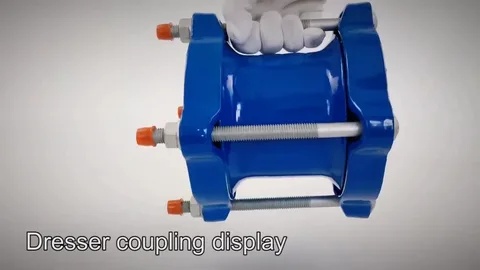

A dresser coupling is a type of mechanical fitting designed to join two pipes together, especially when those pipes are of different sizes, or when there’s a need for quick repairs. Dresser couplings, often made of steel or cast iron, are especially useful in the repair of pipelines under pressure. They’re durable, versatile, and can handle a wide range of applications in various industries.

One of the best features of a dresser coupling is its ability to align and seal the pipes with minimal fuss. When applied correctly, they ensure that there’s no leakage between the connected pipes, preventing further damage to the system. This is why it’s often used in both temporary and long-term fixes.

How Do Dresser Couplings Work?

The design of a dresser coupling allows it to fit tightly around the ends of two pipes, securing them with bolts or other fasteners. It features a gasket inside, which provides a tight seal when the pipes are joined. This prevents any fluid or gas from escaping and ensures that the connection remains solid, even under pressure.

Dresser couplings are generally used for joining pipes in water, gas, and other fluid transmission systems. Because of their robust design, they can withstand high pressures and harsh conditions, making them an essential tool for maintenance and repair of pipeline infrastructure.

I 3D Printed a pipeline dresser coupling. Pretty neat. #pipeline pic.twitter.com/ZO2NI1LXnz

— Russell Nelius (@RussellNelius) January 20, 2018

Why are Dresser Couplings Important?

- Durability: Dresser couplings are built to last. They can handle high-pressure situations and remain functional even in the most demanding environments.

- Ease of Use: Installation of a dresser coupling is relatively straightforward, which helps reduce downtime during repairs. The ability to quickly fix or connect pipes means fewer disruptions to your system.

- Cost-Effective: Instead of replacing an entire section of pipe, using a dresser coupling can be a more affordable way to restore the integrity of your pipeline. It helps save both time and money.

- Versatility: Dresser couplings come in various sizes and materials, making them adaptable for a wide range of industries and applications. Whether you need to connect pipes of the same size or ones that are different, a dresser coupling can offer a reliable solution.

Types of Dresser Couplings

Not all dresser couplings are the same. Depending on the application, there are different types of couplings available to suit various needs. Here are a few common options:

- Standard Dresser Couplings: Used for joining pipes of the same diameter, these are the most common types.

- Flanged Dresser Couplings: These are used for joining pipes that need to be bolted together with a flange, ideal for high-pressure systems.

- Repair Dresser Couplings: Designed specifically for repairing broken or cracked pipes without the need for replacement, they are perfect for emergency situations.

Dresser Coupling Applications in Various Industries

Dresser couplings are not just for water or gas pipelines. Their versatility makes them suitable for a wide range of industries, including:

- Water and Sewage Systems: Dresser couplings are often used to connect pipes in municipal water systems, sewage treatment facilities, and irrigation networks.

- Oil and Gas Pipelines: In the oil and gas industry, dresser couplings are essential for joining pipes that transport crude oil, natural gas, and other products under high pressure.

- Construction and Industrial Projects: From large-scale infrastructure projects to smaller industrial applications, dresser couplings are essential for ensuring pipe systems function seamlessly.

Conclusion: Why Dresser Couplings Matter

In conclusion, a dresser coupling is an indispensable tool for those involved in pipeline construction, maintenance, and repair. The ability to efficiently and effectively connect or repair pipes is crucial for the safety and functionality of any fluid system, making dresser couplings a must-have item in your toolkit. Whether you’re working in construction, maintenance, or industrial settings, understanding the significance of a dresser coupling will help ensure your projects run smoothly.

For more information about dresser couplings and other essential pipe fitting solutions, make sure to check out more articles on DailyScope, your go-to resource for everything related to pipe systems, fittings, and more!

2 Comments

Pingback: Understanding Dresser Coupling: Everything You Need to Know – Site Title

miphxw